Welcome To

Sakshi International Pvt. Ltd.

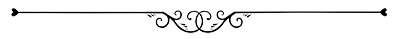

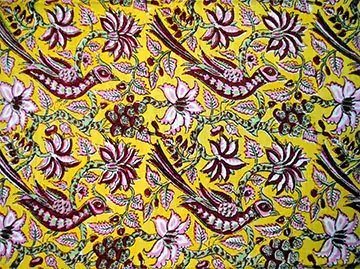

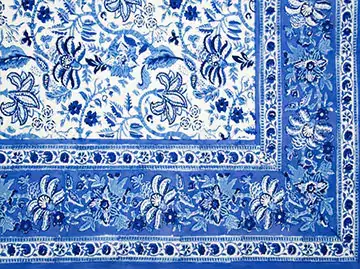

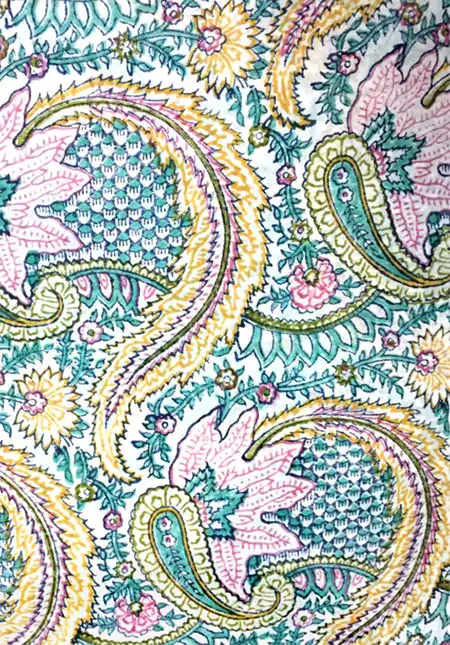

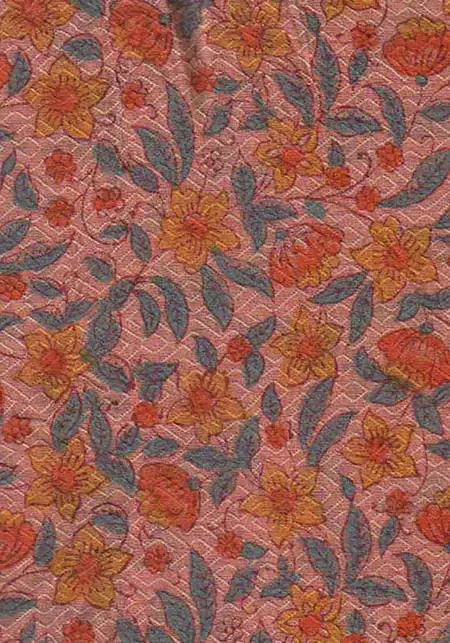

Sakshi International, a leading hand block printed textile manufacturer, is renowned for its exquisite craftsmanship and dedication to preserving traditional art forms. With a rich heritage spanning decades, our company is committed to producing high-quality Jaipur block printing textiles that reflect the timeless beauty of hand block printing. Our skilled artisans meticulously hand-carve intricate designs onto wooden blocks, which are then dipped in natural dyes and pressed onto fabrics with precision and expertise. The result is a collection of vibrant, unique textiles that evoke a sense of artistry and cultural authenticity. Sakshi International takes pride in promoting sustainable practices and supporting local artisans, ensuring the continuation of this remarkable craft for generations to come.

There are different kinds of block printing textiles that have been existent for a long time. Whether it is jaipur block printing or other modern styles of printing, the

major thing to keep in mind is to maintain the quality of the art.

Keeping this idea in minds, Sakshi International Pvt. Ltd has established themselves as one of the most prominent providers of jaipur block printing textiles. Here hand block printed textile manufacturer offer our customers with a variety of designs and patterns for products done with hand block prints.

Read More